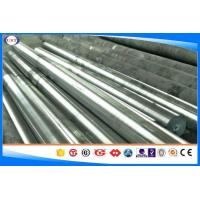

Hardened tool Steel 4H5MFS (4Х5МФСА)

Designation

Description

Steel 4H5MFS used: for the production of forgings of various parts of General machinery; molds for casting under pressure an aluminum and also zinc and magnesium alloys; small hammer stamps; large (thickness or diameter greater than 200 mm) hammer and pressing panels during hot deformation of structural steels and nonferrous alloys in a high-volume mass production.

Standards

Chemical composition

Fe is the basis.

According to GOST 5950-2000 the chemical composition is given for steel grade 4Х5МФС.

According to TU 108.11.917-87 the chemical composition is given for steel grade 4Х5МФСА.

Mechanical properties

Description mechanical marks

Physical characteristics

A description of the physical symbols

Technological properties

SHANGHAI UNITE STEEL

We, Shanghai Unite Steel are committed to integrate

engineering steel resources in china and serve the global

engineering steel market. Our company has more than 15 years of

experience in steel researching, production, managing and sales.

And our team mostly are based on and worked in national famous

steel enterprise.

In the aspect of resources and information, we have established

cooperative and stronger relationship with nearly hundred

enterprises, either state-owned or private owned in china, such as:

DAYE Special Steel-a famous steel enterprise with the longest

steelmaking history; BAO Steel, and Dongbei Special Steel Group-the

biggest special steel manufacturer; TPCO, VALIN-largest seamless

steel tube production enterprise; What's more, we have built long,

deep and close business relationship with dozens of steel

companies, Sharing and holding equities with several steel

enterprises. Because of the close cooperation with steel companies

and our pioneering spirit, which can ensure us stay at the top

competition, and ensure our customers get what they really want!