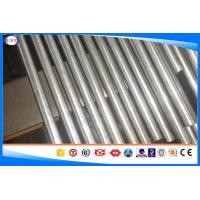

grade AISI E2512 SAE J1249 DIN 1 5681 Bars

Product Details

Chemical composition % of the ladle analysis of grade AISI

E2512 SAE J1249 / DIN

1.5681 Bars and Standards

C(%): 0.09~0.14

Si(%): 0.20~0.35

Mn(%): 0.45~0.60

P(%)≤: 0.025

S(%)≤: 0.025

Cr(%): -

Ni(%): 4.75~5.25

Machining performance

AISI

E2512 the mechanical properties of the report, the report provides

detailed performance analysis and application. Machinability

Long, gummy chips characterize this alloys machinability. It can be

machined in the annealed condition, however condition H1150M will

yield best results. Post machining solution treatment of parts will

be required prior to final hardening if machining in this

condition.

Heat Treatment

CONDITION A--Soak at 1900 F (1038 C) for 30 minutes and cool below

60 F (16 C) for complete martensite transformation. CONDITION H

950- Treat Condition A material at 900 F(482 C) for 1 hour, air

cool.. CONDITION H925, H1025, H1075, H1100, H1150- Soak solution

treated material for 4 hours at specified temperature, air cool,

CONDITION H1150M- Soak solution treated material at 1400 F (760 C)

for 2 hours, air cool, then re-heat to 1150 F (620 C) for 4 hours

and air cool.

Welding

Successfully welded by common fusion and resistance methods, this

alloy should not be joined by oxyacetylene welding. AWS E/ER630

filler metal is recommended if required.

Forging

Soak for 1 hour at 2150 F (1177 C) prior to forging. Do not work

below 1850 F (1010 C). Post-work solution treatment is required

prior to final hardening.