INTRODUCTION

Alloy 321 (UNS S32100) is a titanium stabilized austenitic stainless steel with good

general corrosion resistance. It has excellent resistance to

intergranular corrosion after exposure to temperatures in the

chromium carbide precipitation range of 800 – 1500°F (427 – 816°C). The alloy resists oxidation to 1500°F (816°C) and has higher creep and stress rupture properties than alloys 304

and 304L. It also possesses good low temperature toughness.

Alloy 321H (UNS S 32109) is the higher carbon (0.04 – 0.10) version of the alloy. It was

developed for enhanced creep resistance and for higher strength at

temperatures above 1000oF (537°C). In most instances, the carbon content of the plate enables dual

certification.

Alloy 321 cannot be hardened by heat treatment, only by cold

working. It can be easily welded and processed by standard shop fabrication

practices.

COMMON APPLICATIONS

- Aerospace – piston engine manifolds

- Chemical Processing

- Expansion Joints

- Food Processing – equipment and storage

- Petroleum Refining – polythionic acid service

- Waste Treatment – thermal oxidizers

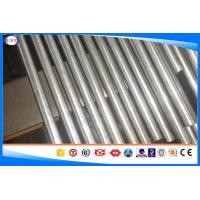

| Steel Grade | 321 / 321H | Application | Aircraft, heat exchangers, etc. |

| Shape | Round Bar | Standard | GB, ASTM, DIN,JIS |

| Dimension | Φ4-800 mm; length below 10m | Surface | Black, Bright, Polished, Peeled |

| Technique | Cold drawn; Hot rolled; Forged | Ultrasonic Test | 100% UT Passed |

What we can offer?

-We offer a wide range of steel products in a wide variety of

dimensions and executions, according to the common international

specifications or customize.

-Machining and heat treatment are available.

-Also, we advise you in choosing the right materials.

Shape Available

- Solid round bar

- Flat bar

- Square bar

- Hexagon bar

- Block

- Plate

- Sheet

- Wire rod

- Strip

Our Advantages

- High mechanical property and quenching, enable the surface share

equal hardness after deal with it

- Good polishing and low roughness

- Making the heat-treatment to harden condition before using it

- Competitive price

- Fast production lead-time

- All the material are inspected with 3 times to meet the highly

standards

- Pure steel quality & stable quality to be guarantee

OUR AVAILABLE STAINLESS STEEL PRODUCTS ARE AS BELOW

PAYMENT AND SHIPPING

1. Both T/T and L/C will be acceptable

2. Trade Terms: FOB, CIF, CFR

3. The delivery will be in 10-15 days if have stock; For customized

items, the delivery will be negotiated by both parties

4. Shipping by sea freight from Shanghai Port (PRC) for Bulk

orders, by airfreight or express for samples

COMPANY INFORMATION

Shanghai Unite Steel Trading Co., Ltd

We are committed to integrate engineering steel resources in china

and serve the global engineering steel market. Our company has more

than 15 years of experience in steel researching, production,

managing and sales. And our team mostly are based on and worked in

national famous steel enterprise.

In the aspect of resources and information, we have established

cooperative and stronger relationship with nearly hundred

enterprises, either state-owned or private owned in china.

What’s more, we have built long, deep and close business

relationship with dozens of steel company, Sharing and holding

equities with several steel enterprises. Because of the close

cooperation with steel companies and our pioneering spirit, which

can ensure us stay at the top competition, and ensure our customers

get what they really want!

FAQ

Q: Are you a manufacturer or merely a trader?

A: We are group of companies and owned manufacturer bases and

trading company. We specialized in special steel which include

alloy structural steel and carbon steel and stainless steel, etc.

All material are with high quality and competitive price.

Q: How do you guarantee the quality of your product?

A: Firstly, we can provide the certificates from the third party,

such as TUV, CE, if you need. Secondly, we have a complete set of

inspection system and every process is checked by QC. Quality is

the lifeline of enterprise survival.

Q: Delivery time?

A: We have ready stock for most of material grades in our

warehouse. If the material doesn't have stock, the delivery lead

time is about 5-30 days after receiving your prepayment or firm

order.

Q: What is the payment term?

A: T/T or L/C.

Q: Can we visit your company and factory?

A: Yes, warmly welcome! We can book the hotel for you before you

come to China and arrange our driver to our airport to pick you up

when you come.

CONTACT US

We are happy to answer your questions and make you an offer for

these and other materials. Contact us now for more information.

Your Contact Person

Ms Chilli Ho

Phone/Wechat/Whatsapp +86-181-0187-5575

Skype: chilli.ho@outlook.com

Email: chilli.ho@shunitesteel.com