1.APPLICATIONS:

Heavy-duty arbors, bushings, wear pins,bearings, sprockets, gears

and shafts etc.

Or can be used for high tensile applications uncarburised but

through hardened and tempered. Severely stressed components for

mechanical engineering and automobile industry .

2.RELATED SPECIFICATIONS:

| Germany | W.Nr. 1.6587 |

| Great Britain | EN 17CrNiMo7/EN 10084 DIN 18CrNiMo7-6/EN355, 822A17, 822H17, 817M17 |

| USA | AISI 4820 |

| ISO | 683-11 18CrNiMo7/683-17 18CrNiMo7-6 |

3.Chemical Composition (%):

Carbon 0.14-0.19

Silicon 0.15-0.40

Manganese 0.40-0.60

Phosphorus 0.035max

Sulphur 0.035 max

Nickel 1.40-1.70

Chromium 1.50-1.80

Molybdenum 0.25-0.35

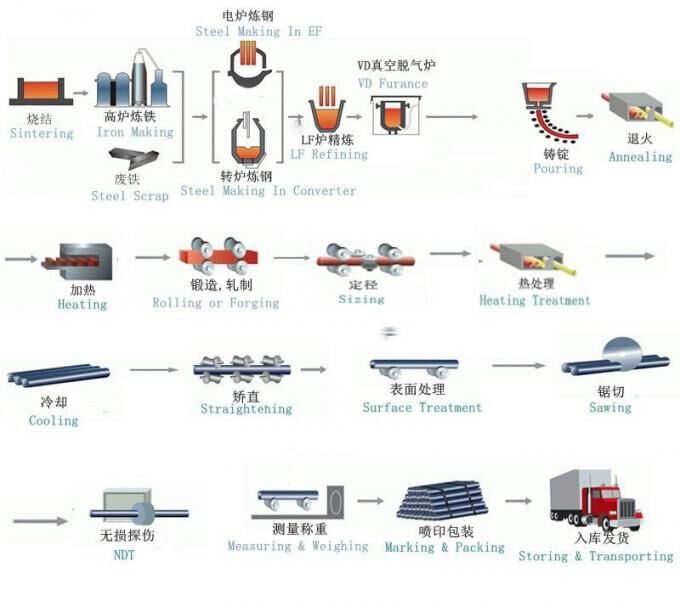

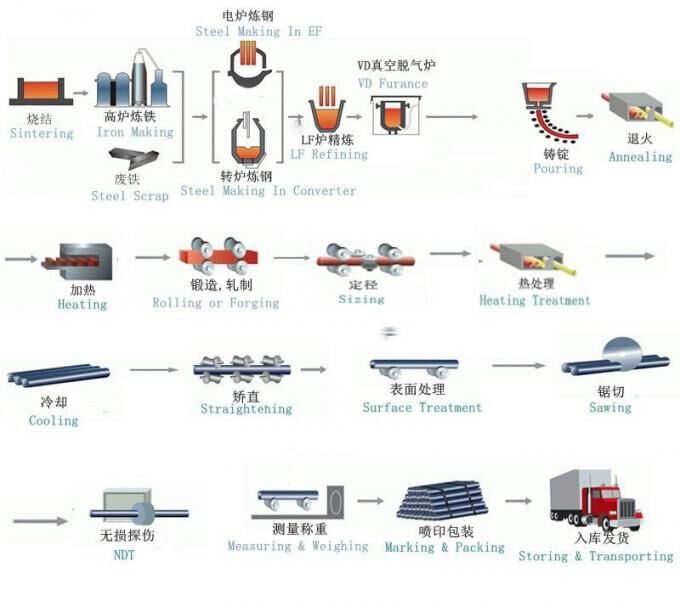

4.Process: EAF+LF+VOD+ Rolled+Heat Treatment(optional)

SIZE RANGE:

Round:

Hot Rolled: 10mm-350mm

SURFACE FINISHES:

Black, Peeled(K12), Cold Drawn, Turned & Polished(H10, H11),

Precision Ground(H9, H8)

Test: Ultrasonic test according to SEP 1921-84

Soft Annealing

Heat to 650-700oC, cool slowly in furnace. This will produce a

maximum Brinell hardness of 229.

Intermediate Annealing: 630-650oC.

Hardening

Carburising: 880-980oC.

Core Hardening: 830-870oC, water.

Case Hardening: 780-820oC, water.

Normalizing

Normalizing: 850-880oC, air.

Tempering

Tempering temperature: 150-200oC.

Soft annealed treated: max. 229 HB.

Treated for cold shearability: max. 255 HB.

Treated for strength: max. 229 HB.

Treated for ferite and pearlite structure and hardness range:

159-207 HB.